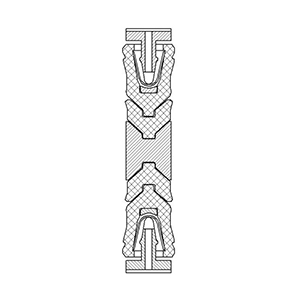

A seal assembly for use in a wellbore tool, it acts as a flow restrictor protecting a lower end of the seal assembly from high pressure and/or high volume flow.

Brand:

JST SealsItem NO.:

ESYPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50

Seal stack for well tools sliding sleeve

In many well completion operations, it frequently occurs that it is desirable, either during the completion, production, or workover stages of the life of the well, to have fluid communication between the annular area between the interior of the casing and the exterior of the production tubing or workstring with the interior of such production tubing.

A seal assembly for use in a wellbore tool, it acts as a flow restrictor protecting a lower end of the seal assembly from high pressure and/or high volume flow.

In such well tools, a series of upper and lower primary seals are placed in the housing for dynamic sealing engagement relative to the exterior of a sleeve which passes across the seals during opening and closing of the port element. As with the seal stack, such primary sealing means also represent an area of possible loss of sealing integrity.

Application:

1. FLS and FLS-R Gate Valves

2. Well tools like sliding sleeves that can be used for infinitely adjustable switches

2. Bi-directional pressure bearing piston or rod seal

|

Features:

1. High temperature and high pressure resistance 2. Bidirectional alternating pressure bearing 3. Reciprocating seal 4. High reliability - verification of over 2400 reciprocating tests 5. JST patented seal design |

|

Technical Parameter |

|||||

|

Temperature range |

Pressure |

Medium |

Material |

Compliant with standard |

|

|

4℃~177℃ |

≤15000psi |

water, oil, natural gas, fracturing fluid, H2S |

PC005/PC002/PC007/PEEK/HNBR/FKM |

API 19LH V1 standard |

|

Existing Standard Grooves:

G=4.76 L=45.5

G=6.35 L=38(50.8)

G=7.94 L=42.6

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2024 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat