Are you still troubled by finding a Fugitive Emissions Valve Stem Packing?

Reducing fugitive emissions has become a high-priority goal for nearly all processing plants and facilities around the world.

Often, the valve technology itself has a significant impact on fugitive emissions and therefore the life cycle cost of the equipment.

According to the research, one of the largest sources of fugitive emissions in plants is associ ated with valves. The bulk of valve emissions come from the valve stem packing, which has a very difficult duty to perform. It must contain the process and avoid leaks, yet still allow the valve stem to move freely. This is a design challenge for any valve, but it is particularly difficult with a rising stem valve that cycles up and down repeatedly.

With each stroke, the packing tends to wear along the stem, allowing process media to escape. This is particularly troublesome on valves that also encounter pressure and temperature swings. There are improved packing designs that can reduce these emissions and extend maintenance cycles, but inherently a rising stem design is difficult to seal consistently.

To better help control fugitive emissions in API valve systems, JST R & D center has come out a valve stem packing design which is workable for both API 6A and 6D valve stem. This design have been verified in our customer’s lab.

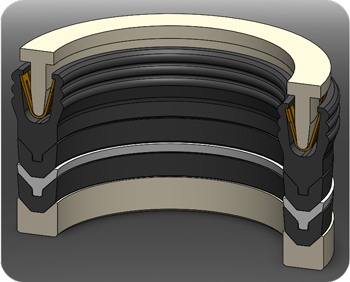

JST ESY design is a common dynamic seal for ball valve and gate valve stem, this seal with different V-rings and T-shape support rings can be used for fugitive emission valves and meet the requirements of ISO-15848. The seal materials have good air impermeability and are also very suitable for oil, gas and other acid, alkali or H2S working conditions.

The seal consists of a U-shaped jacket, a spring, a V-shaped ring, a C-shaped anti-extrusion ring and a T-shaped support ring. In some special applications, the back pressure may reach to a certain level and damage the seal. The T-shaped support ring can protect the U-shaped jacket and prevent the lip of the U-shaped jacket from being damaged.

Technical requirements:

Working pressure: ≤10000PSI;

Working temperature: -100℃~+260℃;

Material Composition:

U-Shape jacket: modified PTFE (PE001): resistant to high temperature and high pressure, wear resistance, low creep;

V-Shape ring: modified PTFE (PE001): resistant to high temperature and high pressure, wear resistance, low creep;

V-Shape ring: pure PTFE (P1020): extremely low friction coefficient, strong air tightness, ultra-low temperature resistance;

T-Shape Support ring: polyetheretherketone (PK002): high strength, corrosion resistance, wide application temperature range;

C-Shape ring: polyetheretherketone (PK002): high strength, corrosion resistance, wide application temperature range;

Spring: golden alloy spring,with very good corrosion resistance, high and low temperature resistance.

Characteristics:

Resistant to high temperature & high pressure;

Compatible with chemicals of acid, alkali or H2S;

Low friction and low gas leakage rate.

Note: Materials shall be varied for different appllications, If you have special requirements (pressure, temperature, speed, special media, etc.) for Fugitive Emissions Valve Stem Packing, feel free to reach out for the sealing solution.

New Blog

© Copyright: 2025 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat