Item NO.:

EVZPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

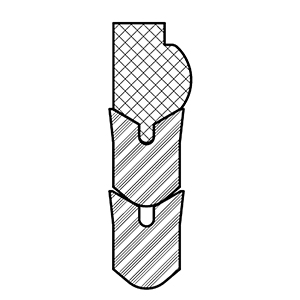

50Well service plunger pump packing

In order to eliminate extrusion and provide excellent wear resistance for fracturing, acidizing and cementing pumps, JST has developed high performance well service pump packings; It provides maximum sealing for high-pressure oil well service pump.

Used in various fracturing and cementing applications.

Used where high pressure, chemical fracturing and carbon dioxide are present.

Used for extreme performance under high pressure and where abrasive proppant is required.

|

Advantages:

1.More cost-effective |

|

Working Conditions |

||

|

Temperature range |

Pressure |

Medium |

|

-46℃~+165℃ |

≤20000 PSI |

mud, acid liquid, emulsion, hydraulic oil |

Previous:

Fabric reinforced well service packingNext:

Oil Scraper Seal for Scrap Excess Lubricating OilIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2024 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat