Choosing seals for a cryogenic valve

Choosing the right seal for cryogenic valves is critical to ensure reliable performance in extremely low-temperature environments. Here's a detailed guide to help you make an informed decision:

Key Factors to Consider:

1: Operating Temperature Range

Cryogenic valves typically operate at temperatures as low as -196°C (-320°F) for liquid nitrogen or even lower for liquid helium. Ensure the seal material maintains its integrity and flexibility at these temperatures.

2: Chemical Compatibility

The seal material must resist degradation from the media, such as liquefied natural gas (LNG), oxygen, nitrogen, helium, or hydrogen.

3: Seal Type

Choose between dynamic (for moving parts) and static seals based on the application. Dynamic seals require higher flexibility and wear resistance.

4: Pressure Ratings

Seals must handle the operating pressures while maintaining a tight seal.

5: Regulatory and Safety Standards

Ensure the seals meet relevant standards such as ISO, ASME, or specific certifications for oxygen service.

6: Seal location

Different locations will use different seal designs.

Recommended Materials:

1: PTFE (Polytetrafluoroethylene)

Advantages: Excellent chemical resistance, low friction, and stability at cryogenic temperatures.

Limitations: Low elasticity, requiring backup rings or specific designs to maintain tightness

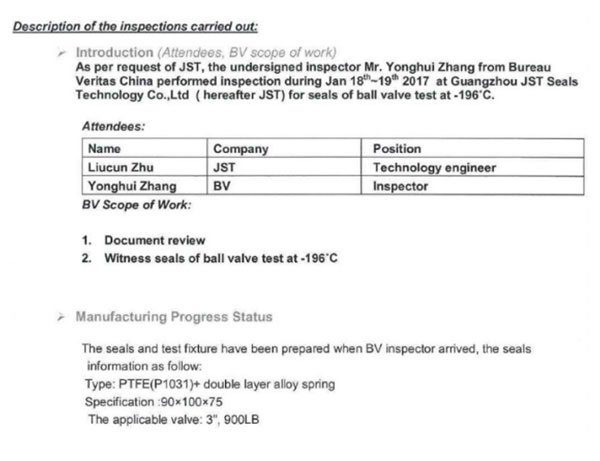

JST has rich experience in designing cryogenic valve seals.

BV witnessed the whole test process.

New Blog

© Copyright: 2025 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat