How FFKM Elastomers contribute to Critical Applications

Application of FFKM in O-Rings, seals and gaskets can meet the chemical resistance and high temperature requirements of strictly regulated industries.

Equipment operators in critical and strictly regulated industries such as oil and gas, chemical refining and processing, aerospace, pharmaceutical and food processing, and semiconductor chip manufacturing all face a common pain point: How can the elastomeric materials in the O-rings, seals, and gaskets that keep the machines moving meet the stringent requirements of their environments?

The answer is Perfluoroelastomers (FFKM), a family of chemically and heat-resistant elastomers that combine the chemical resistance of polytetrafluoroethylene (PTFE) with the flexibility and elasticity of standard fluorocarbon elastomers (FKMs).

FFKM was born and is now widely used in many industrial processes. However, due to the wide variety of compounds currently available, there are many factors to consider when selecting FFKM materials.

The Benefits of FFKM

FFKM is usually applied in where other polymers cannot perform well. One advantage of FFKM is that it is fully fluorinated and therefore contains standard FKM, resulting in a higher temperature rating (up to approximately 325°C [617°F]) and better chemical resistance with nearly universal chemical compatibility. The combination makes seals made from FFKM the first choice for the industry's most demanding applications.

As mentioned above, a formula is different from a compound, which is usually a mixture of ingredients with specific properties.

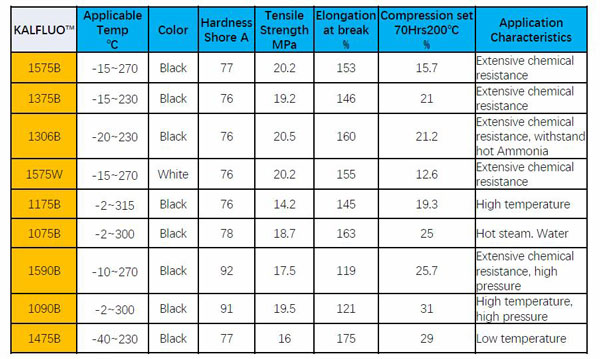

Take JST KALFLUOTM for example, KALFLUOTM is manufactured, cleaned with deionized water, and packaged in a cleanroom. It was built for use in harsh environments. With a high chemical resistivity, it is able to withstand the chemicals used in semiconductor manufacturing as well as withstanding the solvents used for cleaning. It is also formulated for the high temperatures in developing semiconductors

When selecting a FFKM, consider what performance attributes your application requires. In addition, the FFKM must meet specific certifications and approvals.

How To Use FFKM Seals in Industrial Applications

The chemical processing, oil and gas, food and beverage, and semiconductor industries provide opportunities to study more carefully why and where FFKM can be used.

Chemical Processing

In the chemical processing industry, selecting materials for equipment components is crucial as corrosive chemicals, high temperatures, and challenging operating conditions are commonly present. FFKM materials have become an indispensable solution due to their excellent resistance to various chemicals, including acids, bases, solvents, and corrosive fluids.

FFKM materials are widely used in the chemical processing industry, from seals and gaskets to diaphragms and valve components. FFKM can withstand harsh environments, ensure process integrity, and improve equipment reliability

Typical chemical processing applications for FFKM parts and seals include wet chemical fluid handling, chemical etching, and heavy-duty cleaning processes.

Main characteristics of FFKM

Compared to standard FKM, FFKM aims to provide:

More stable at temperatures up to 325℃ (617℉)

Wider working temperature in between -46 to 330℃ (-50.8 to 626℉)

Excellent chemical resistance and vacuum application performance

More effective sealing

More flexible in application

Oil and Gas

Sealing solutions play a critical role in various applications in the oil and gas industry, ensuring the integrity, safety, and efficiency of equipment and operations. From exploration and production to refining and transportation, harsh and demanding environments pose unique challenges that require reliable sealing solutions.

During the exploration and production phases, wellheads, valves, pumps and other equipment use sealing technology to prevent the leakage of fluids such as oil, gas and drilling mud. These seals must withstand the high pressures, extreme temperatures, corrosive fluids and abrasive contaminants common in downhole environments.

During refining processes, seals are utilized in pipelines, reactors, distillation towers, and storage tanks to contain hazardous chemicals, prevent leaks, and maintain optimal operating conditions. The seals must resist exposure to aggressive chemicals, high temperatures, and mechanical stresses associated with refining operations.

Seals are used in pipelines, reactors, distillation towers, and storage tanks during the refining process to contain hazardous chemicals, prevent leaks, and maintain optimal operating conditions. Seals must be able to withstand corrosive chemicals, high temperatures, and mechanical stresses associated with refining operations.

Sealing is crucial for maintaining the integrity of pipelines, valves, and fittings, ensuring safe and efficient long-distance transportation of oil and gas. These seals must be able to withstand environmental factors such as temperature fluctuations, vibrations, and external pressures, while preventing unorganized emissions and minimizing the risk of accidents to ensure safe and sustainable operation.

Overall, the successful application of sealing technology in the oil and gas industry requires innovative design, high-performance materials, rigorous testing, and compliance with strict safety and environmental standards. By meeting these challenges, sealing solutions help improve the reliability, continuity, and profitability of global oil and gas operations.

Typical applications include completion tools, drilling and wireline tools, valves, pumps, compressors, process instrumentation, packing systems, mechanical seals, and downhole drilling tools.

Semiconductor Manufacturing

In the semiconductor industry, where precision, reliability and contamination control are critical, FFKM materials play a key role. FFKM materials are known for their excellent resistance to extreme temperatures, harsh chemicals, and aggressive plasma environments, making them an ideal choice for critical semiconductor manufacturing processes.

From the sealing application of semiconductor equipment to wafer processing, FFKM materials have unparalleled performance, ensuring process integrity and minimizing downtime caused by material failures. The sealing solution has key characteristics such as low plasma erosion rate, high temperature stability, excellent resistance to various chemical processes (dry and wet), and outstanding sealing performance.

In addition, all FFKM seals are manufactured and packaged in a clean room environment to maintain product purity. Typical applications include lithography machines, wafer processing machines, and wafer surface processing machines.

Food and Beverage Processing

In the food and beverage processing industry, different machinery is used at every stage from raw materials to finished products and consumer goods. The industry faces a series of significant challenges in sealing.

Extreme temperature range: O-rings and seals used in industry must withstand significant temperature changes. From cold storage conditions to high-temperature cooking and sterilization processes, the integrity and durability of the seal must be maintained.

Chemical resistance: Cleaners and chemicals are often used in food processing environments to maintain hygiene. Therefore, the seal must have high chemical resistance to prevent degradation that may cause leakage and potential product contamination.

Wear resistance: The inherent continuous mechanical motion during the operation of processing machinery requires seals to have excellent wear resistance and durability. High pressure technology also exerts pressure on these critical components.

Food safety regulations: All seals used in food processing must be food grade, non-toxic, and comply with strict food safety regulations. Compliance ensures the health and safety of consumers and protects manufacturers from potential legal issues related to food safety.

In summary, FFKM elastomers have many advantages. When considering fluids and gases that interact with elastomers in specific applications, talk to our team today about what the affordable, highly durable, customizable, and readily available KALFLUO® can do for you.

New Blog

© Copyright: 2025 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat