V-stacks for both uni- and bidirectional HPHT and LPLT applications

When using elastomers and thermos plastics in critical service applications, there are a number of options in terms of seal configuration and material choice that effectively seal and provide maximum product reliability. These combinations vary based on the sealing conditions faced.

JST design engineers pick the best matched material characteristics for optimum seal performance. JST teams focuses on designs of multiple redundant seal stack combinations for both uni- and bidirectional HPHT (High Pressure High Temperature) and LPLT (Low Pressure Low Temperature) applications.

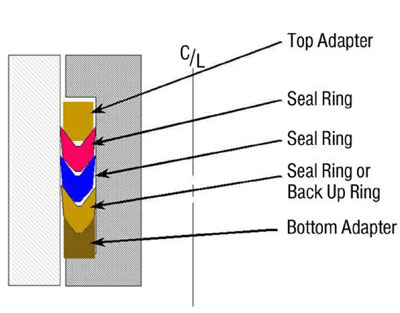

V-stacks were introduced from a redundancy perspective but used the same compound across the stack. JST introduced the composite stack that combines different elastomers, thermoplastics and metals to cover all service conditions. The following design geometries incorporate materials developed specifically for downhole environment.

Bi-directional

This design incorporates end adapters, center adapters and combinations of steel, elastomeric, Ryton (PPS) and filled PTFE V-rings. The combination of elastomer, steel and thermoplastic will seal at both HPHT and LPLT.

Bi-directional—Nonelastomeric

This design incorporates end adapters, center adapters and combinations of thermoplastic and filled PTFE V-rings. The combination of elastomer and thermoplastic will seal at both HPHT and LPLT. The multiple redundancy concept ensures reliable sealing.

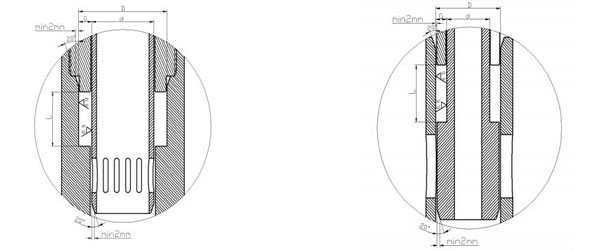

V-stack seals groove drawings as following. The main dimensions d,D, L need to be provided.

JST design team is capable to design the best seal stacks base on the operating conditions and groove dimensions that our client provides.

New Blog

© Copyright: 2025 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat