Gate valve equipment seals

JST seals produce high-quality throttle valve and gate valve equipment seals.

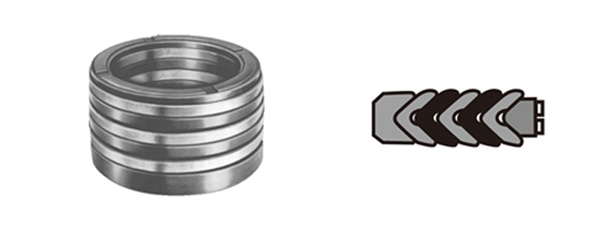

Choke packing throttle valve are control valves for production wells, which are used to control the flow of well fluid under production. The throttle valve also compresses the pressure from the reservoir and regulates the downstream pressure in the flow line. Choke packing is available in a variety of types and material configurations for standard and sour gas applications.

The valve stem seal uses a chemically insert seal sleeve and contains an elastic spring element to ensure positive sealing in high or low temperature applications.

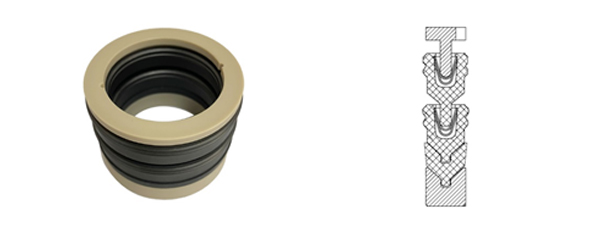

U-packing seals are most commonly used in oilfield valves. In these valves, poor sealing conditions and bad media will be encountered, and they are equipped with PTFE jacket and nitrile or FKM packing.

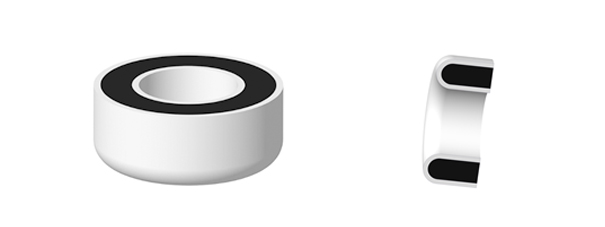

Inner and outer seat seals are widely used as valve seat sealing rings for high-pressure valves. Generally, the ID and OD face seal rings of the valve seat are used together. Its sealing jacket is made of polytetrafluoroethylene composite material or PEEK, which has good anti leakage and anti extrusion performance.

The PTFE gate valve seat seal for type FC, FLS and FLS-R gate valves is made of durable teflon, it is compatible with the Cameron gate valve type FLS, and used in rotating equipment to minimize o-ring movement.

JST seals have a wide range of valve seals for all types of gate valves, including stem packing seals and components, bonnet sealing rings, seats and body bushings, and our inner and outer seat seals for high pressure or high temperature applications.

New Blog

© Copyright: 2025 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat